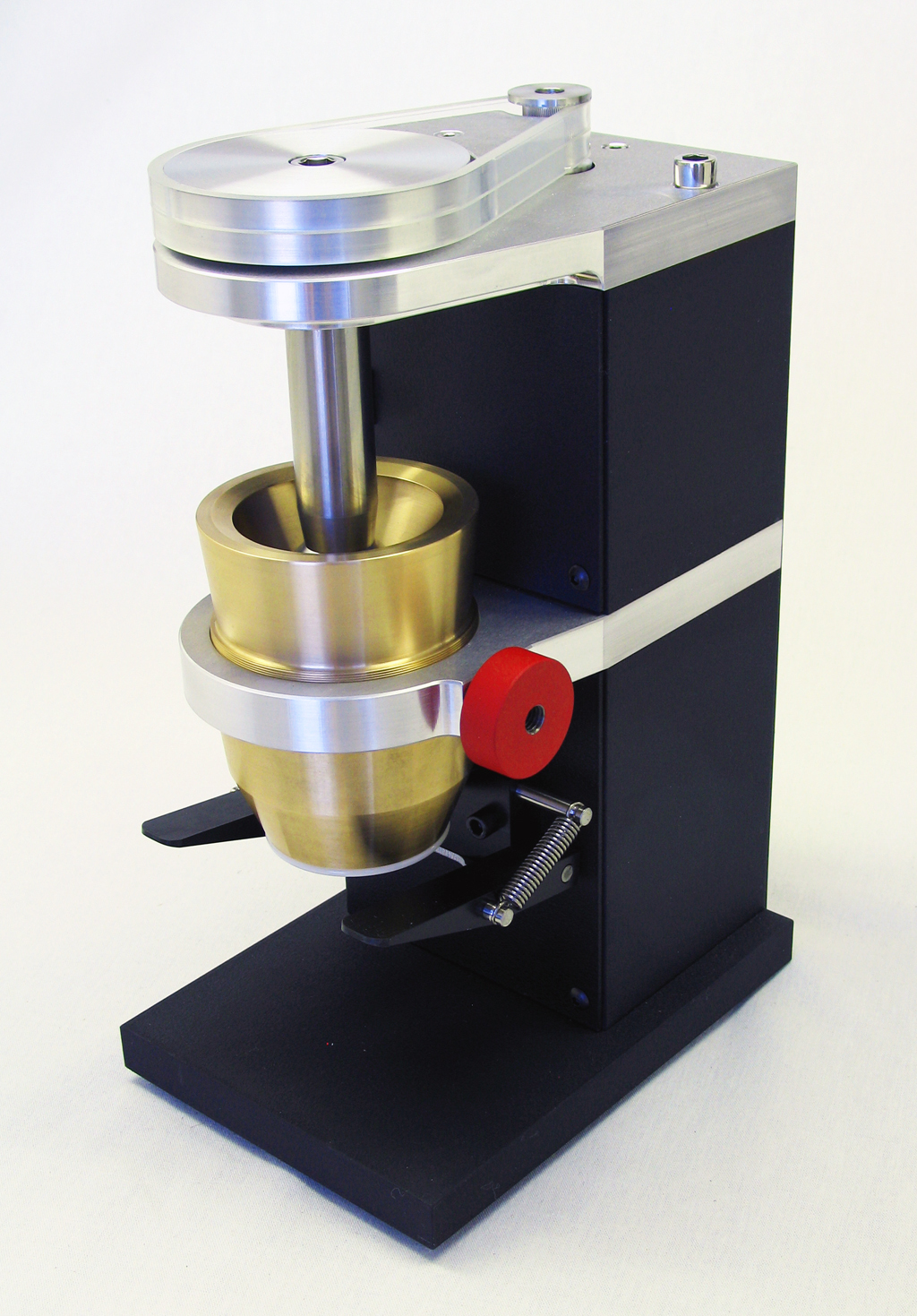

The Versalab M3 Grinder, and now the M4, first introduced in 2005, is the original and still the finest single dose espresso grinder. It is loved for its flavor and reliable design in homes and coffee shops the world around. Continually refined as the espresso grinder market evolved, it is made to the highest industrial machine standards. See below for the latest upgrades, and a kit to upgrade an M3 drive system to M4 specification.

The design answers all the requirements of making a voluptuous cup of espresso. That it can make a brilliant Turkish or press pot grind comes as a plus.

The main requirements for an espresso grinder are to limit the mistreatment of the coffee.

• Cut the beans over a long grind path minimizing rubbing and smashing.

• Use a cool running DC motor, well away from the grinding chamber, minimizing heating.

• The straight through grind path and no retention prevent stale flavors.

• Provide a good particle distribution in the porta-filter. Eliminate post grind grounds manipulation.

• Minimize the time from grind to brew - protect delicate volatile flavors

The M4 accomplishes these things to a singular degree.

Details of design.

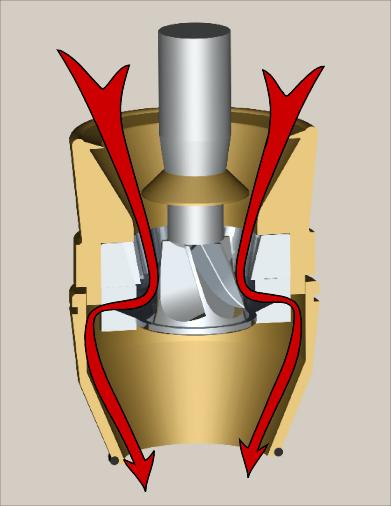

• Conical burrs combined with 68mm. flat burrs. Total grind path of 40.6mm or about the equivalent of 96+mm. flat burrs.

The burrs are a combination of conical and flat. The beans are dropped into a conical area where they are broken into small pieces. These pieces are then small enough to enter the flat burrs to be finished ground to the chosen size. This is a compact burr set with a long and easy grind path, minimizing harsh treatment of the coffee and producing fluffy non-oily grounds.

All the coffee entering the grinder leaves via the bottom funnel in a circular fluffy deposit into your portafilter.

• Simple and rapid workflow. Minimizing the evaporation of flavors volatiles.

No need for wetting the beans or dressing the grounds — a light tap to settle, and ready to tamp. This ensures no delay into the espresso machine, thus ensuring no loss of all the volatiles.

• Grind fineness is adjusted by turning the top funnel, infinitely variable. The fine thread of this adjustment allows a small movement of the top funnel to change the grind size by about .00005” ( a little over a micron) or 1/60th the thickness of a human hair.

• The motor is a DC motor made by the premier US manufacturer. Burr speed is 500 rpm.

Quality and manufacturing

Grinder parts are produced by an aerospace and defense machining company here in Albuquerque New Mexico. Allowed variation in dimension ranges from +/-.002” to +/- .0002” depending on the parts requirements. Some of the parts are then powder coated, others are hand finished by custom equipment at Versalab.

Accuracy of the moving parts and their finished alignment is checked multiple times throughout assembly in Versalab’s shop. The design, manufacturing accuracy, and attention to detail combine to create a superb coffee grinder.

Grinder $3,480

Grinder with portafilter holder $3,665

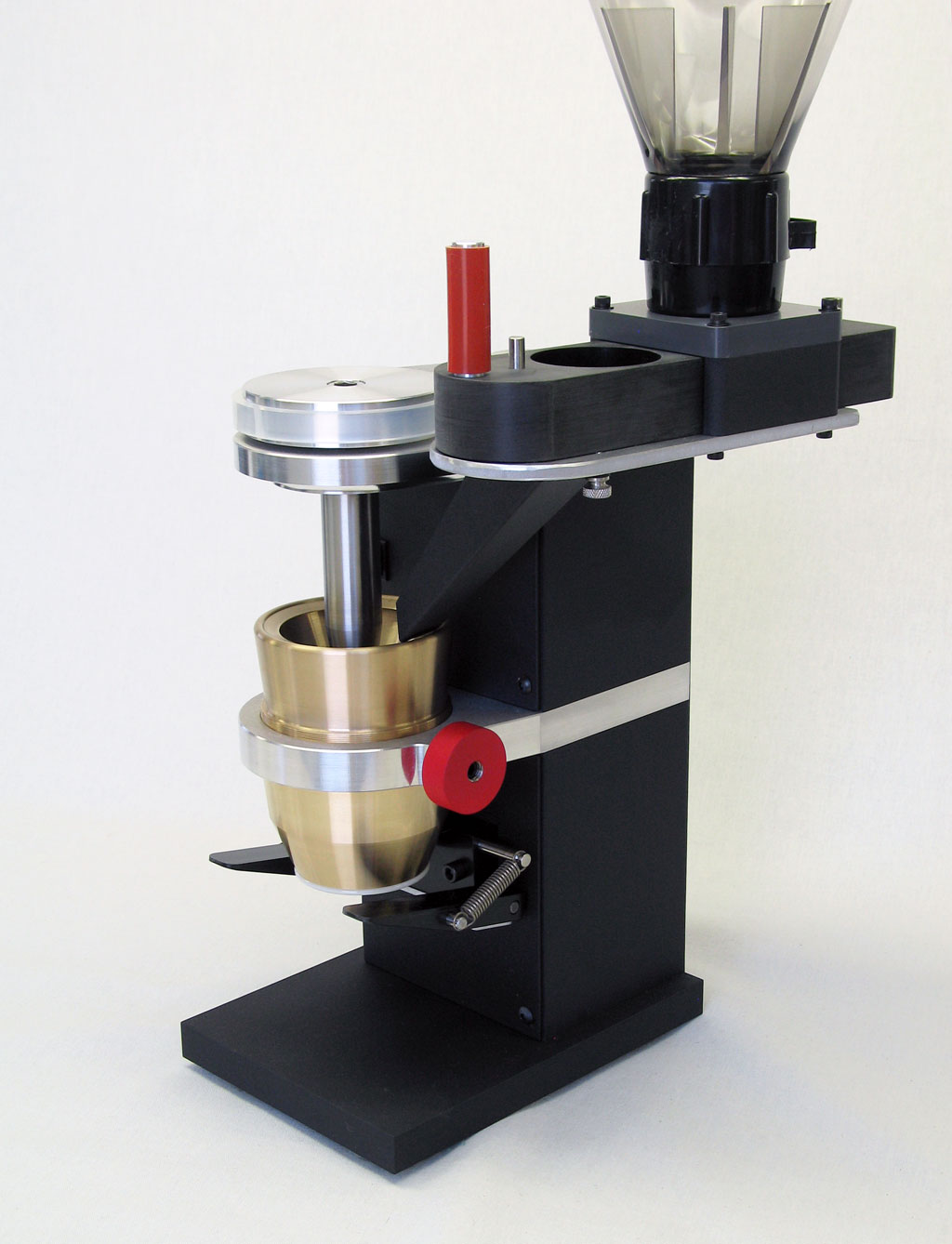

Dosing Hopper 1 kilo $475 each

Dosing Hopper ½ or 1 lb. $495

specify right or left side

Dosing ring set $92

Lid for top funnel $28

included if desired with grinder

all FOB factory New Mexico

Warranty 1 year - support forever

Each grinder is made to order. No returns.

International customers pay their country's customs duties and taxes

Weight 37 lbs

6” wide x 13” high x 8” deep

(not including the power cord)

Standard 1 kilo hopper adds 5 1/2" per side. Total height becomes 25 3/4", depth becomes 12 1/2".

Medium 1 lb. hopper makes the machine 22 5/8" tall.

Short 1/2 lb. hopper makes the machine 20 1/4"

Operates from 115 - 240 volts AC. 50/60 Hz

Kit to upgrade the drive system of an M3 to M4 specification. Field installable.

The cost of the kit is $525 + shipping. It includes a new rear cover with the electronics already installed. All five connections to the grinder are easily managed by hand. Tools are provided to remove the original circuit board, and to accomplish the drive belt installation.

In addition a new small (motor) pulley and two belts are supplied.

CALL 505.771.9177 or EMAIL

to BUY or for more INFORMATION

GRINDER CHANGES BY YEAR & SERIAL NUMBER

2005-2007

#37 on – distance between bottom of funnel and base plate increased by 1/2" to 5 ¾”. [Dec ‘06]

#48 – shipped with scale for optional customer fit. [June ‘07]

2008 #73 - 108

#98 – thicker felt pad feet to reduce noise for consumer kitchen counter.

2009 #109 - 135

#121 – added bottom funnel clips. [June ‘09]

#127 – changed to red adjustment lock knobs. [Sept ‘09]

#134 – bottom funnel texture changed and added food safe wax. To help prevent grounds retention. [Dec ‘09]

2011 #175 - 236

Build 48 Dec. 2011 #234 – bad burrs. Bradbury’s couldn’t grind fine enough. [Dec ‘11] Sent back to us; we tracked down problem and fixed it.

Several other grinders from that time also had the problem of not being able to grind fine enough – all resolved with replacement burrs. The manufacturer allowed too great an exit hole for the grounds.

2012 #237 - 331

Build 60 Late Aug 2012, #299 onwards Big pulley/shaft bolt torqued to 200 in/lbs.

2013 #327 – 387 [except 331 which was incl. in 2012]

Build 73 June 2013 # 356,7,8,9 – and onwards. Shafts pressed into bearings, checked for run out. Glued into top plate. Recheck run out. Top of grinder frame dowelled together within .002”. From this time on, misalignment is not possible unless the machine is damaged (even shipping dropping wouldn’t alter alignment). Radial run out within .003” TIR, axial within .0004” TIR.

2016 #522 - 572

Build 114, Nov., #555 onwards 17-4 ph stainless steel small pulleys. Quite hard. The original design of knurled aluminum pulleys were found to be wearing the knurling. The new pulleys will last a very long time.

2017 #572 - 621

Build 128, Nov., #612 on - tighter belts, slight increase in speed to 550 rpm. To provide better grinding with light roasts.

2019 #700 -on

Now renamed M4. Incorporates new motor speed control circuit board. Speed 480. Dual belt system. SSP burrs as standard. Cosmetically revised top funnel.

• Versalab has completely upgraded the burr drive system. The increasing desire for light roast espresso has finally obsoleted the original system. The same DC motor is now driven with a very smart speed control board that has demonstrated its ability to prevent belt slippage while driving harder than the previous motor board. The drive belts have also undergone an upgrade. Now using two 3/8” wide belts, rather than the original 1/2” wide, the torque capacity is 150% of the previous design. The M4 ships standard with the original design burrs now made for us by SSP.

The new Lid